Standard:

EN 50288-7

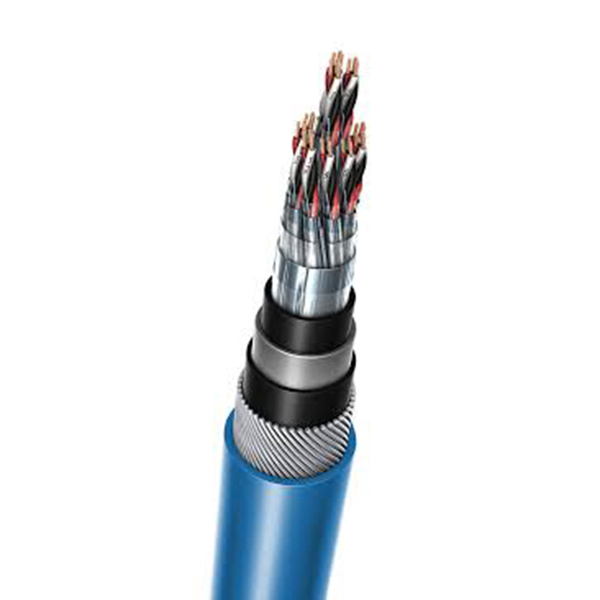

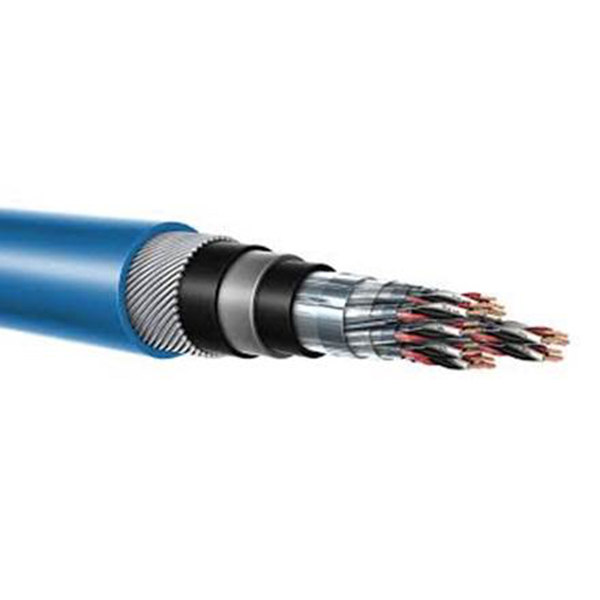

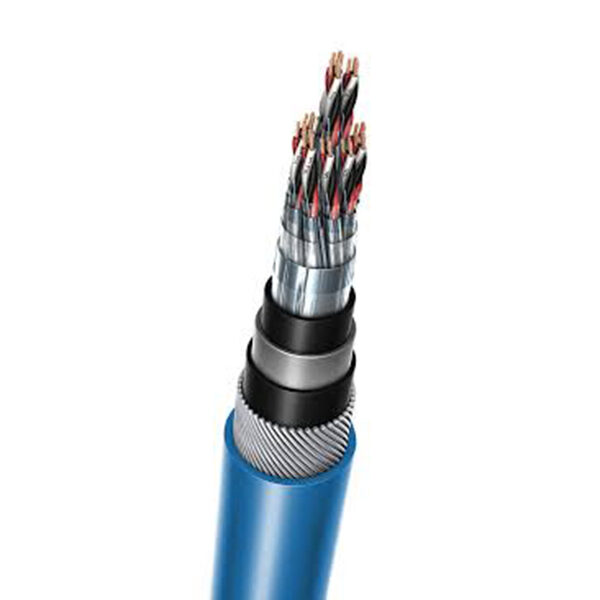

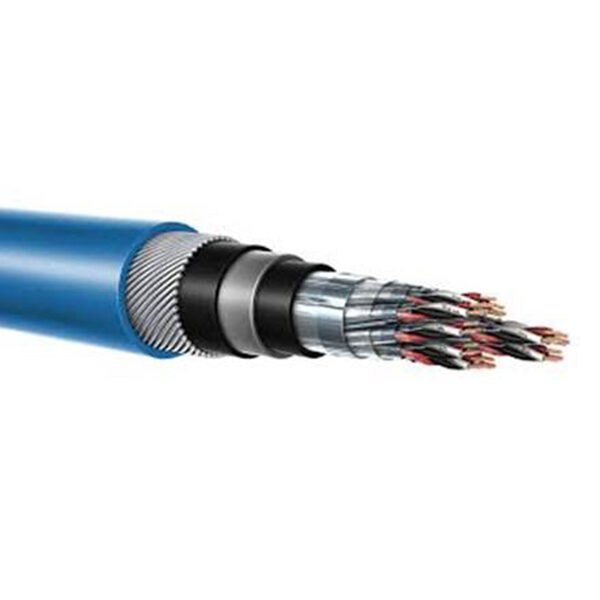

CONSTRUCTION:

Conductor: Solid (cl. 1), stranded (cl. 2)

or flexible (cl. 5) copper conductors

(annealed or tinned) (EN 60228)

Conductor cross section: 0,5 mm2, 0,75 mm2,

1,0 mm2, 1,3 mm2, 1,5 mm2, 2,5 mm2

Insulation: polyethylene (PE), Cross-linked polyethylene (XLPE) or Polyvinyl chloride (PVC)

Colour insulation: a-black, b-white (300V) or blue (500V) (marked with numbers), c-red

Twisting elements: pairs or triples

Individual screen: Aluminium polyester tape (Al/PET) with solid tinned copper drain wire, longitudinally

Cable core: screened pairs or triples stranded in layers in cable core

Wrapping: At least one layer polyester tape

Collective screen: Aluminium polyester tape (Al/PET) with stranded tinned copper drain wire, longitudinally

Inner sheath: polyvinyl chloride (PVC) sheath

Armour: galvanized round steel wires (SWA) (diameter 0,9 mm, 1,2 mm, 1,6 mm, 2,0 mm, 4,0 mm)

EN 10257-1

Outer sheath: polyvinyl chloride (PVC) sheath, black or blue colour RAL 5015 (intrinsically safe systems).

Behavior in fire:

Self-extinguishing cable acc. to IEC 60332-1/

EN 60332-1/VDE 0482-332-1

APPLICATION:

These multi-element metallic cables are designed for the signal transmission in instrumentation, analogue and digital communication, and control applications in process plants such as those found in the petrochemical and power generation industries. Cables are recommended for indoor and outdoor installations, on racks, in conduits, in dry and wet locations; for direct burial.

The permissible temperature range:

– during installation: from -5°C to +50°C

– during operation (Y, 2Y): from -30°C to +70°C

– during operation (2X): from -30°C to +90°C

Min. permissible bending radius:

– during operation max. 10D

(D – outer diameter of cable)