Standard: SRPS N.C5.360

DIN VDE 0250-812

Nominal voltage

U0/U: 0,6/1 kV

Test voltage: 3 kV for energy, 2 kV for control cores

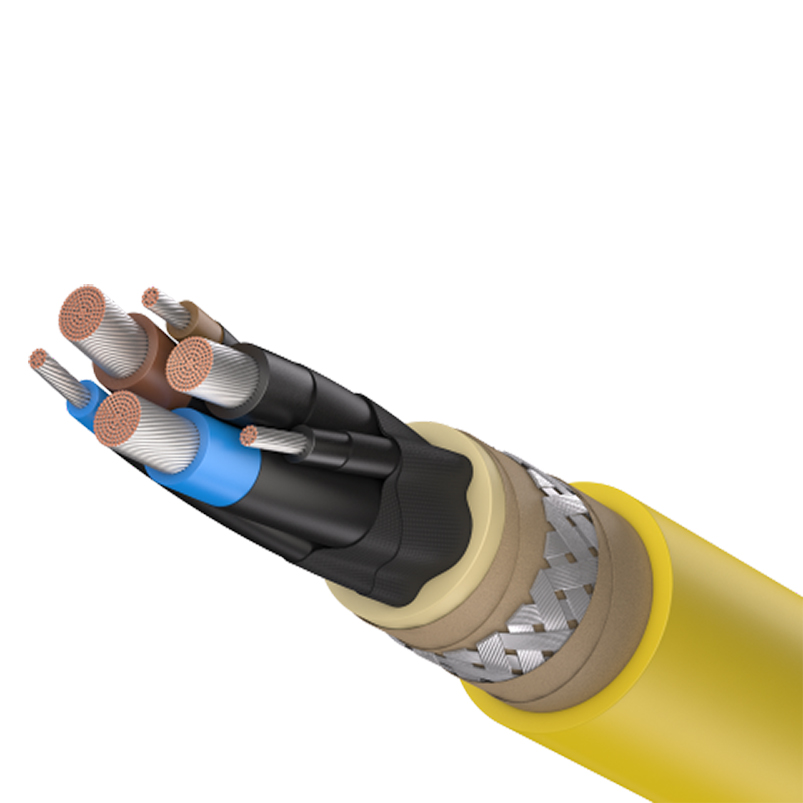

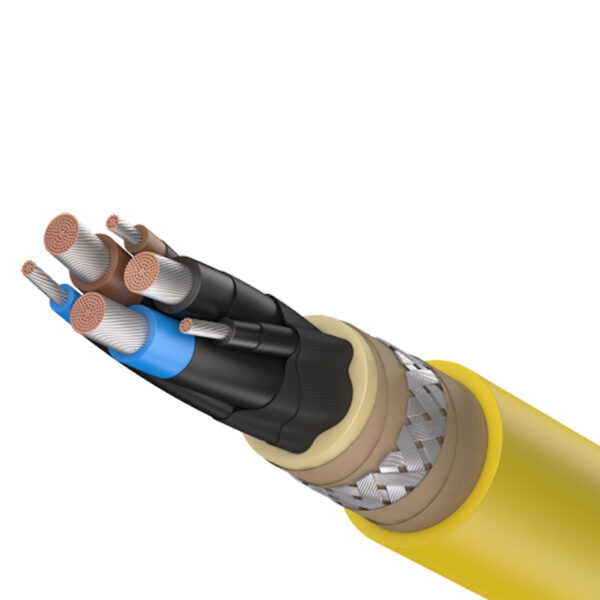

CONSTRUCTION:

Power cores

Conductor: tinned copper conductor class 5 acc. to

SRPS N.C0.015 (IEC 60228)

Insulation: rubber compound based on ethylene-propylene elastomere

GI2 (SRPS N.C0.190); 3GI3 (DIN VDE 0207-20)

Semi conductive layer: rubber compound/tape

Command cores

Conductor: tinned copper conductor class 5.

Insulation: based on EPR rubber.

Semi conductive layer: rubber compound/tape.

Control core

Conductor: tinned copper conductor class 5.

Semi conductive layer: rubber compound/tape.

Cable core: 3 energy core with 2 command and 1 control conductor placed in the intermediate space

Inner sheath: based on synthetic rubber

(GP2, SRPS N.C0.190), GM1b(DIN VDE 0207-21)

Concentric electrical protection: tinned copper wire or rope, a combination of tinned copper and galvanized steel wires

Sheath: rubber compound on polychloroprene basis (CR) (Neoprene), GP7 (SRPS N.C0.190); 5GM5

(DIN VDE 0207-21), yellow colour.

Oil resistant: DIN VDE 0472-803, metod A

Flame-retardant: according to IEC 60332-1

APPLICATION:

The cable is intended for use in mines with underground pits, threatened by fire and gas and coal dust explosion (methane pits). It is used for connecting machines for cutting and loading coal, machines for making underground corridor, as well as for supplying appliances and devices, electrical lighting and auxiliary electrical circuits.

Permissible conductor temperature:

– max operating temperature +90°C,

– in short circuit (max 5 s), max +250°C

Permissible ambient temperature:

– mobile from -25°C to +40°C,

– fixed laying from -30°C to +40°C

Smallest bending radius: 5D (D – cable diameter)