Standard: IEC 60794; VDE 0888

CONSTRUCTION:

Optical fibers:

SM – single mode optical fibers (9/125 µm)

(G.652D, G.655, G.657A1/A2)

MM – multi mode optical fibers (50/125 or 62,5/125) according to ITU-T Recommendation

Material of fibers:

a) core – Silicon glass: (SiO2) doped with Germanium Dioxide (GeO2);

b) cladding: Silicon glass (SiO2)

c) primary protection: Dual layer of UV-cured acrylate resin

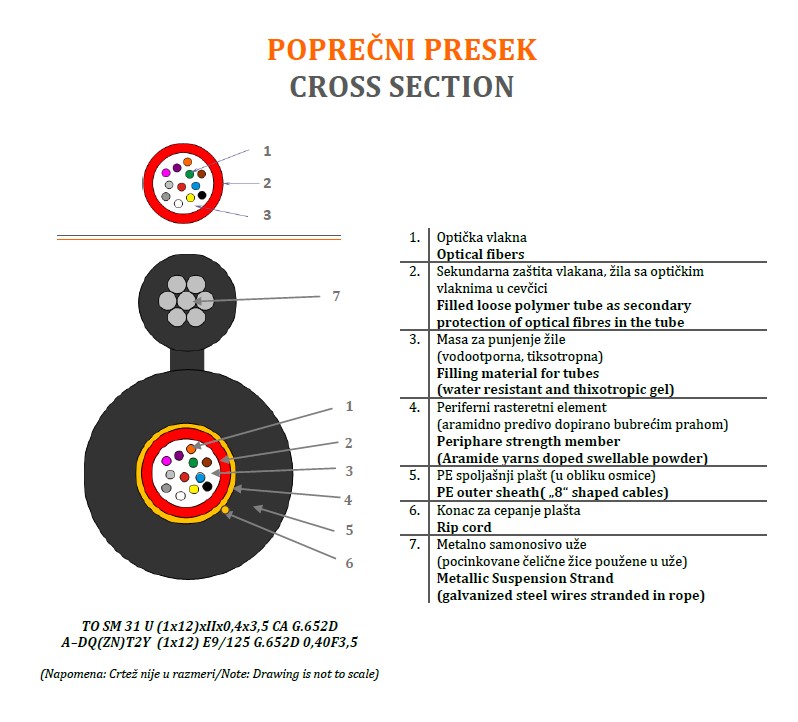

Secondary protection of fibers: Filled loose polymer tube of PBT elastomer, filled with tixotropic jelly mass, loose laid fibers within tube – SZ stranded

Tube material: Polyester PBT-Polybutylene Terephtalate

Fibers and tubes designation: IEC 60304, TIA/EIA-598;

DIN VDE 0888

Cable core:

Central tube: cable core is without FRP and in one tube placed max. 24 optical fibers

Peripheral supporting elements: Aramid fibers doped with swellable powder are used as water and mechanical protection.

Sheath ripcord: one or more ripcord placed under outer sheath.

Metallic Suspension Strand: Galvanized steel wires stranded in self-supporting rope

Sheath: HDPE – high density polyethylene, black. Cable core are connected with the suspension wires by PE sheath to form a figure “8” shape.

APPLICATION:

These optical cables are use for outdoor application, for telecommunication networks: post, railway, distribution TV signals. They are used for installation on overground posts. Suspension stranded rope provides high tensile strength.

The permissible temperature range:

– during installation: from -30°C to +60°C

– during operation: from -30°C to +70°C

– during storage and transport: -40°C to +70°C

Min. permissible bending radius:

– Operation: 20D

– Fixed: 15 D (D – diameter of cable)

Tensile strength, max. (kN): On customer’s request