Standard: SRPS N.C5.230

DIN VDE 0276-603; DIN VDE 0276-627

HD 603 S1; HD 627 S1; IEC 60502-1

Nominal voltage U0/U: 0,6/1 kV

Test voltage: 4 kV

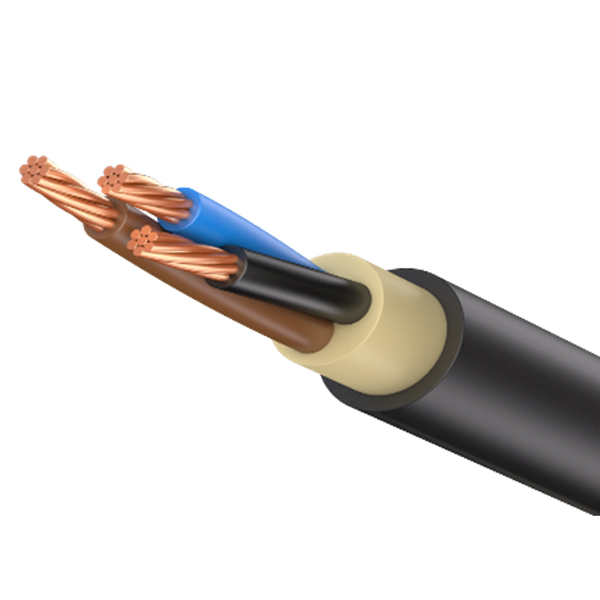

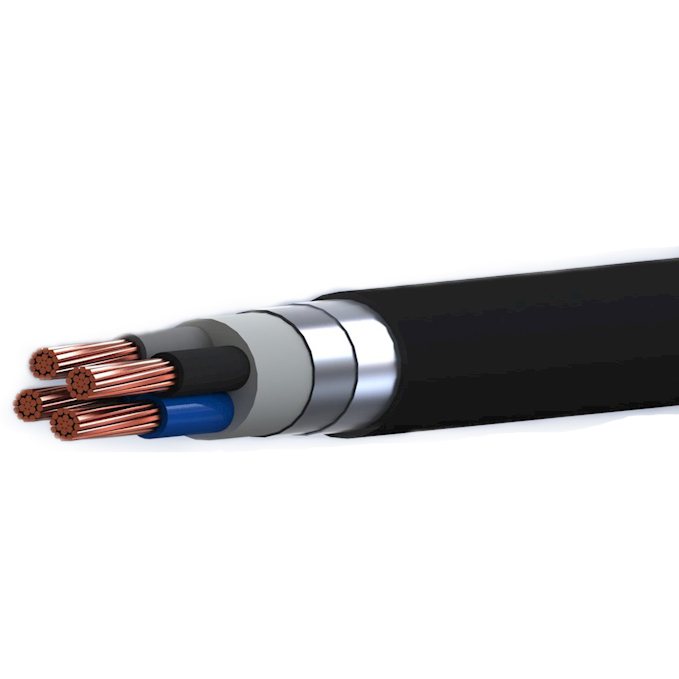

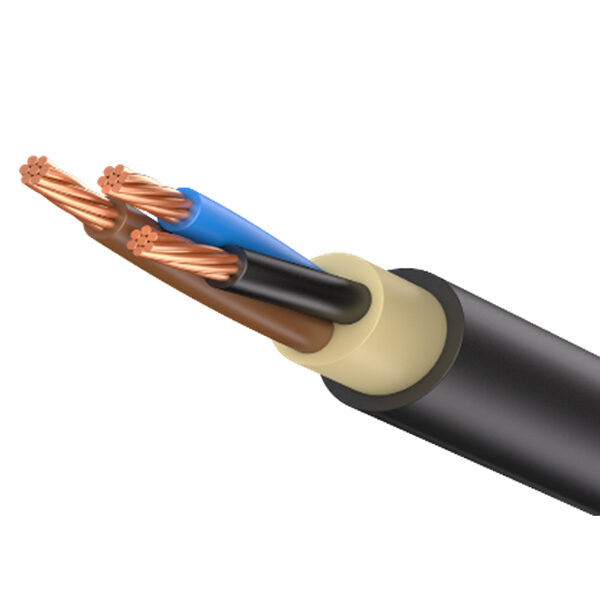

CONSTRUCTION:

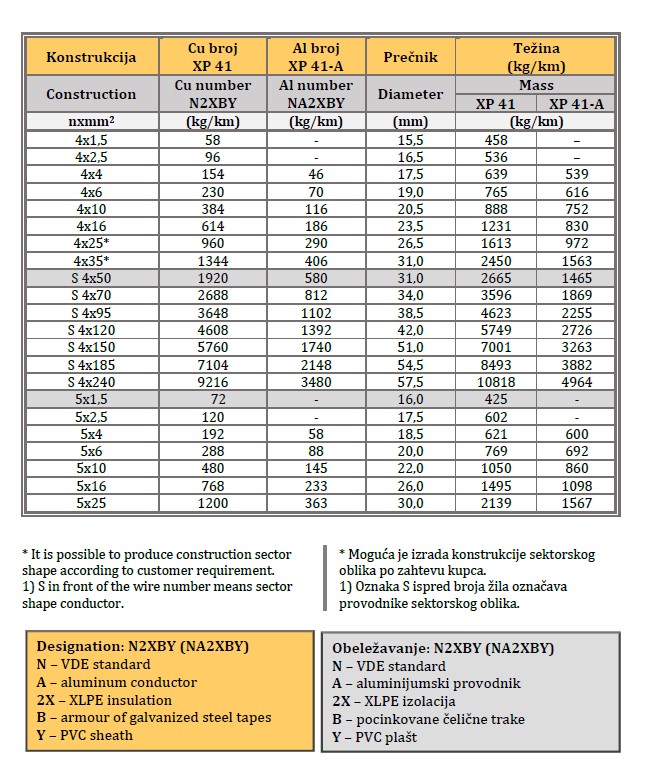

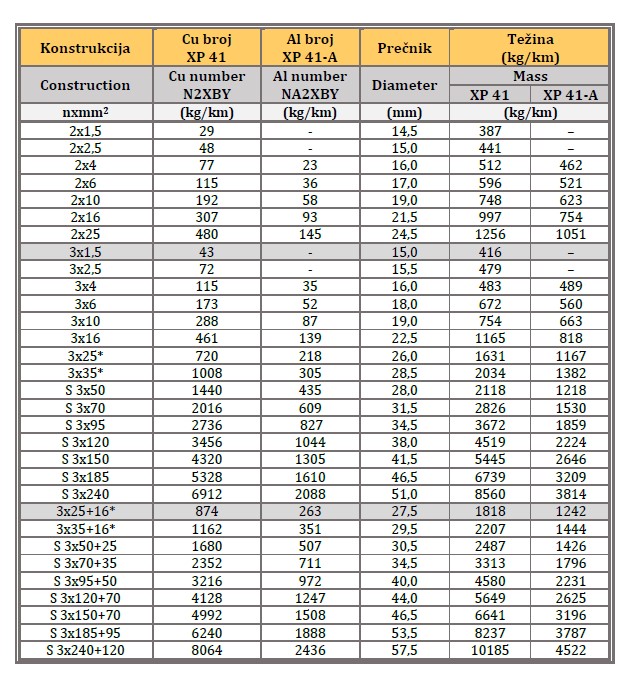

Conductor: wire or rope, class 1 or 2, according to SRPS N.C0.015, IEC 60228,

copper: type XP 41 (N2XBY), or aluminium:

type XP 41-A (NA2XBY).

Insulation: XLPE compound

Colour code: according to HD 308 S2;

VDE 0293-308

Core: two or multi cores are stranded together.

Fillig: non hygroscopic, non vulcanized rubber compound layer or thermoplastic compound layer. For cables with sector-shaped conductors (label S in the table) wrapper of thermoplastic tape.

Armour: wrapped two galvanized steel tapes.

Sheath: PVC compound (IEC 60332-1).

SheatH colour black (UV protection).

APPLICATION:

For laying in earth, indoors, in ducts, in the open air in urban networks, industrial plants and electric power plants, when mechanical damage could be expected, due to rodents and hand tools.

Laying on sloping grounds or cable hanging is not allowed.

Permissible conductor temperature:

– max operating temperature +90°C

– in short circuit (max 5 s), max +250°C

– short-term overload in emergency operation to +230°C

Permissible environment temperature:

at laying and handling, min +5°C.

BENDING RADIUS (min.):

– single core cables 15D;

– multi core cables 12D (D – cable diameter)