Standard: SRPS N.C5.230

DIN VDE 0276-603; DIN VDE 0276-627

HD 603 S1; HD 627 S1; IEC 60502-1

Nominal voltage U0/U: 0,6/1 kV

Test voltage: 4 kV

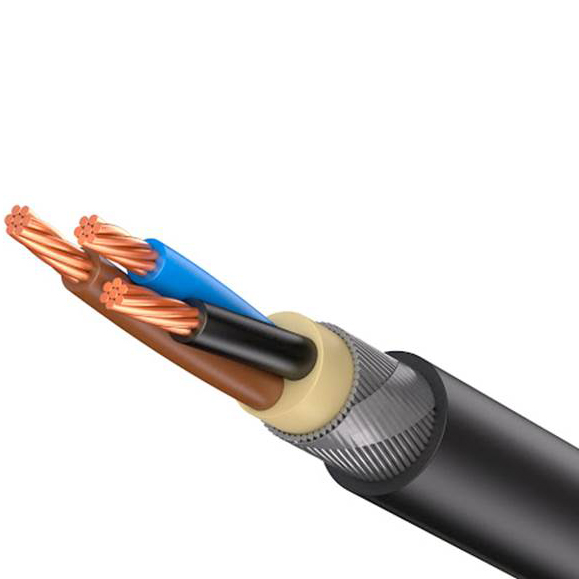

CONSTRUCTION:

Conductor: wire or rope, class 1 or 2, according to SRPS N.C0.015, IEC 60228, copper: type XP 44 (N2XRGY), or aluminium: type XP 44-A (NA2XRGY).

Insulation: XLPE compound.

Colour code: according to HD 308 S2;

VDE 0293-308

Core: two or multi cores are stranded together.

Filling: non hygroscopic, non vulcanized rubber compound layer or thermoplastic compound layer.

Armour: wrapped zinc-plated round steel wire with or without contra helical zinc-plated steel tape (obligatory when cable is used in mines).

Sheath: PVC compound (IEC 60332-1).

Sheath colour black (UV protection).

APPLICATION:

For laying in earth, indoors, in ducts, in the open air, in the water, when additional mechanical protection is required when cable is exposed to mechanical tensile strain during laying and use. For use in mines according to Techn. standards for electrical plants, equipments and installations in mines, as well as horizontal and vertical installation in places where there is a height difference in mines, including methane holes.

Permissible conductor temperature:

– max operating temperature +90°C,

– in short circuit (max 5 s), max +250°C.

– short-term overload in emergency operation to +230°C

Permissible environment temperature:

at laying and handling, min +5°C.

BENDING RADIUS (min.):

– multi core cables 15D (D – cable diameter).